Seeing Is Believing

There is something inherently mesmerizing about being in a place where people use simple materials to create art. Shapes, hands, tools and creativity all working together in tandem to give shape and infuse passion. These are some of the feelings I got during my visit to the Carlos Santos Factory this week.

An ordinary man from a tiny village in Southern Greece, now working with his idols and the people that changed his life. Year 2020 will be a fantastic year, especially now that we are all slowly shedding the labor of 2019 and can finally reap the rewards.

Today, I am proud to show you everything I can from the Factory, explain you the process behind each step of the Carlos Santos production and what does the future hold for The Noble Shoe.

This year is to go even further than beyond. Bonus points to whomever got the reference.

What Is Your Obsession With Carlos Santos Kostas?

So many of you ask me why did I choose Carlos Santos and not just any brand. It all started after receiving my first Wine Shadow Patina Double Monk Straps. It felt like a completely different game coming from the underwhelming (albeit decent) Loake 1880.

I am a man that likes value and quality. Shoes are an expensive hobby and I feel above a certain price point you get diminishing returns. Of course, that is true only if you are not an enthusiast. You learn to appreciate constructions, the work that goes behind it, the little details. It is magnificent!

Then there is the connection. The genuine family connection I have with the people behind the brand. I finally feel that I have purpose. My purpose is to offer amazing shoes and show the world how to do it right. All decisions, all roads of my life led to this very moment. This is what I am meant to do.

Oh and after seeing what I saw in the factory, I am pretty sure Carlos Santos is the value king.

The Carlos Santos Factory – Stairway To Heaven

One can find the Zarco factory about 30 minutes south of Porto in a little area called São João da Madeira. It is a very big establishment in an industrial area and you cannot miss it. The brand logo sits gently above the entrance.

Immediately climbed the marbled stairs to find the reception and the showroom. Ana Santos gave me a big hug and it was so special for me. Inside the sliding room there was a heaven of shoes. Models and colors of any possible combination which define a generation. Things that most people will never see or know exists however I promise you it is true.

I was also the first person to see the 2020 collection which they will present next month in Milan. Unfortunately I cannot share with you photos yet but I can tell you they are some very interesting models!

Handgrade & Handcrafted Buffet

A surprise for me was the amount of shoes from the Handgrade and Handcrafted Line. Especially the latter since they are notoriously hard to find online. However I can tell you that you can compare them to Crockett & Jones Handgrade for a lower price.

Strong Focus On The Current Models

Right there one can also find the current line up or the flagships if you may say. From Oxfords to Jodhpurs and Sneakers with stunning patinas, they have it all.

While it might not be something super unique as many shops can offer the basic models, it is a whole different game seeing some special patinas live for the first time and visualize it. They do make pretty pictures too!

Patinas & Soles Like No Other

It was the first time I ever saw the CS1942 in real life. The most expensive, premium, limited edition of a shoe Carlos Santos ever made. Only 150 of those will find happy owners around the world. Every piece of it is special, including the box and the incredible sole.

By the way the box you see above is the standard box which comes with the Handcrafted Line of shoes. Talk about unique huh?!

Carlos Santos Can Do Exotics

Now here’s something I bet you didn’t know. Carlos Santos is perfectly capable of working with exotic leathers such as crocodile, python and stingray. Although they did tell me stingray is a very difficult material to work with and often breaks the needles.

Here’s a closer look at the Stingray model. Not my cup of tea, but unique nonetheless!

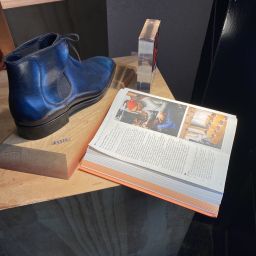

Last but not least I want to show you one of the most unique patinas I saw in my life which is the Ocean Patina. It is incredible how artists can put so much depth in a pair of shoes to elevate it to another level.

Split Toes, Boots & Loafers Are The Name Of The Game

If we began talking about how many models and styles there are out there we would finish tomorrow. However I do want to share some more pictures and models before we discuss the actual process.

Lastly, some gorgeous sneakers that I am pretty sure I will stock soon in The Noble Shoe.

Hot Tip: If you want to know more about leathers and especially exotics make sure to read the Leather Guide!

Into The Factory

After a quick tour in the office it was finally time to visit the Mecca of Shoemaking. Sitting on a perch next to a small staircase that leads to the magic. It was the perfect vantage point to get a good idea of how everything works.

Tons of lasts, leathers, machinery and people buzzing around in their daily life, creating, painting and designing.

On the right next to the stairs one can find a small enclosure where they design shoes. It always fascinates me to see how people can put a piece of paper and translate it into a 3D drawing.

Oh now that we are at it you should have seen my face light up like a kid when I met Mr. Carlos Santos himself. I also got the chance to meet his son that works with more private labels.

Then you move to the other area where everything starts from. Leather cutting which very skilled people do by hand with the aid of state of the art machines. Ana told me even though the machinery is super advanced nothing can replace a good pair of hands.

Only the finest leathers with no blemishes make the cut and this is imperative for the quality of the shoes. Usually their calf comes from the best French Tanneries whereas the Suede from the best English one.

Two people man this station one opposite to the other and meet in the middle of the table before moving on.

Let’s Talk About Production

Now we stumble upon a small issue. The only restriction was to not include visible clear faces of the workers or any private labels. This made it very challenging to actually take pictures or videos so the narrative will be mostly written.

However, I have a few superb videos that show the construction of the soles and I will upload them in high resolution on YouTube. Look forward to them!

The middle section of the factory is the Stitching and Patina. The former is of course the assembly of the leather pieces so you can proceed with lasting them while the latter takes a finished product and applies the hand painting. I always marvel at the sight of skilled people giving a unique identity to each pair of shoes.

Tip: If you are in the US and enjoy Custom Patinas make sure to check my good friend MbShoedoc.

U-Shaped, Just Like An Adelaide!

The magic happens afterwards. On the left you have an assembly of big noisy machines and operators in a U-Shaped line. Each step and machine represents a different part of the shoemaking process.

For example, when you get the uppers on the last you need to fasten them and steam it. Leather is quite stiff by its own and everything has to be inch perfect.

After the lasting you need to move forward and prepare the welt. Yet another sophisticated machine does the stitching with precision using a needle and welt attachment. Carlos Santos usually does a 270° Welt but some models use 360°. There is really not much of a difference. Since I want to learn shoemaking this is a scary process for me and their composure is remarkable. After all most have worked in the factory for years and decades.

Now the sole is my favorite part of course! While the Handgrade line has a tight fiddleback waist the Handcrafted one has an even tighter. Watching it molded in real time was incredible. I cannot wait to upload the video! Essentially the operator uses a machine that sculptures the waist after trimming it and leaving a channel open. Afterwards you close it and retain this clean closed channel look.

Cork Filling & Soling

The next step is naturally filling the cork but not before you sand down and even everything. Additionally, you need to add the shank which in this case is wooden. Here’s a (not so great) picture from the video I will share later.

Interesting trivia, all the shoes have wrapping around them to ensure nothing else gets damaged or smeared. It only comes off during the final stage of production.

Cork filling ensures comfort and takes the shape of your foot the more you wear it which is the trademark of the Goodyear Welted Construction. Who doesn’t love comfort?

Wrapping Things Up

We are getting towards the final stages of production which is adding the sole and finishing the shoe. Skilled craftsmen not only stitch the sole but also have to ensure the shoe looks perfect, dye the sole correctly and pass it forward.

What I really want to add is that everyone was so friendly to me. It does not matter if they spoke English or not they just went out of their way to show me. They even let me hold the shoes during production. I remember at a point I asked Ana Santos to adopt me.

In the end, each shoe goes into a rack, all finished and shiny and into its box awaiting new adventures across the globe. I also got the chance to visit the basement with a big stock of leathers and utilities which showed me the sheer scale of things. The Carlos Santos factory can pump out a maximum of 400 shoes per day or over 600000 shoes per year. That is pretty impressive although they don’t operate at full capacity.

What Did I Learn?

Shoemaking is no easy job especially in such scale. The machines they use are incredible and the automation makes you wonder what is possible. It allows to save time and while not “Handcrafted” it still produces impeccable quality when the man and woman behind them are experts. Which brings us to the next point of course.

Nothing would be possible without them. The people that use the machines know everything and nothing can replace a good pair of hands. A machine cannot feel the leather or sense the pore or the saturation. A machine works but the shoemaker guides.

Tip: Please read the “Handmade vs Handcrafted Guide” for more info on the subject.

I also learned that Ana Santos is as wonderful as I expected. I really felt welcome there and she went out of her way to stay with me all day. Porto is a beautiful city with good food and nice weather and one of my considerations to move there next year. Talking about Ana, I gave her a really big hug and it surprised her. She said clients are not usually so warm and feel awkward but this is where I thrive. I thrive among people with passion, love and warmth.

No Factory visit would be complete without a group picture with Mr. Carlos Santos himself! I think you can spot a fake smile from a mile away and this is not one of them! Little Kostas from a town called Thouria in the middle of nowhere right in between his heroes.

The Carlos Santos Factory Visit – Unforgettable Joy

Joy is the world I could think of. It took me a long time to take my mind off things going on around me. Forgetting, forgiving, moving on. I want to formally thank Ana for all the help she continues giving me. Emilia for taking care of my orders and tolerating my 1 million emails during these 6 months. Zahraa for being one of the reasons I am here right now. Mr. Carlos Santos himself for changing my life and lastly all the people that work there and proved to me that passion still exists and that I made the correct choice.

Lastly, people like Bojan, Mike, Konstantin and the dozen others that chose to support my efforts. I thank you all. Even you that hurt me the most. Happiness is a journey, not a destination. Make 2020 your year and never let go.

Enough Greek philosophy though! I hope you enjoyed my article about the visit to the Carlos Santos Factory! Next week I will have a review for you of a nice pair of Monk Zip-Boots all the way from Vietnam. Subscribe to never miss a thing and see you next week!

Thank you for reading,

Kostas Mandilaris,

Misiu Academy

Such an incredible experience. Lucky you

Thanks for reading!