It’s Good To Be Back

It’s Good To Be Back

Revisiting the Carlos Santos Factory was something I wanted to do for a long time.

Since my first visit in 2020 a lot has changed and I wanted to walk you through with a new perspective.

Join me in this short, informative article about last week’s trip.

Almost 4 Years Later

It was just a couple of months before Covid hit the deck and confined us to a miserable 2 years.

Before that though, everything was still open and accessible.

It was also an extremely important time for me as I just decided to go full time on my business.

Just 3 weeks ago I had quit my side-job at Suitsupply to focus completely on The Noble Shoe.

What better way to celebrate than to finally go and meet the people that changed my life.

I ended up going to the factory and spending a wonderful day, learning for the first time how a big shoe company operates.

Fast forward almost 4 years later and here I am, revisiting the Carlos Santos Factory with a successful business and a lot of plans.

Most importantly, I now have the bespoke shoe education to see the production in a different way and understanding.

I hope it shines through.

Tip: You can read the original Factory visit here.

All The Same Internally

Not much (if anything changed) when it comes to the layout and the experience itself.

There are still machines that are decades old (but of course refurbishes) mixed with modern, state of the art machinery.

I remembered and knew exactly where things were and I enjoyed that sense of familiarity.

We went there as a team with my investing partners so it was an exciting time for them to have a tour.

It is interesting to see that other people have a new perspective of me and my knowledge at this stage.

They even asked me to essentially do the tour for my colleagues which I relished.

Oftentimes I feel that the passion for shoes is no longer there, but it sparks into life when I am in my element.

It’s a lovely experience to be able to look at a step in production or process and know exactly why or how.

Of course, I cannot show you everything since some are confidential machines and private labels.

Cutting & Assembling

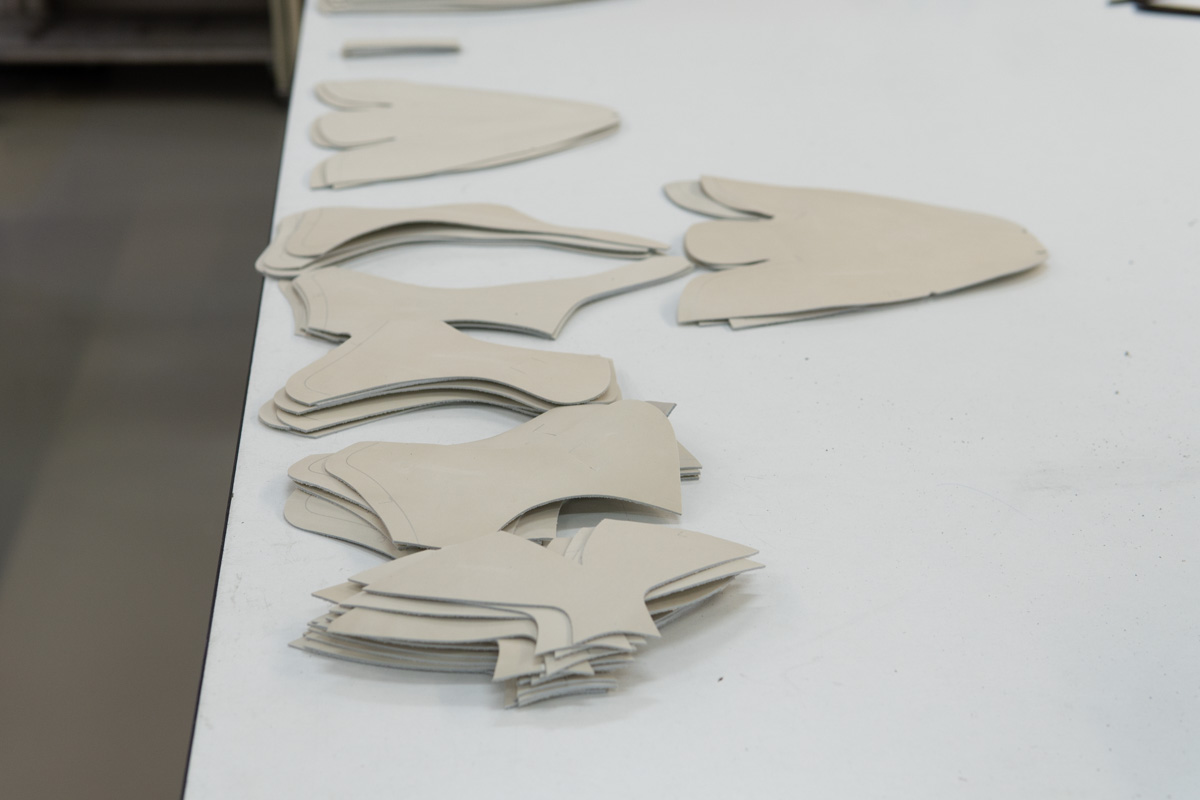

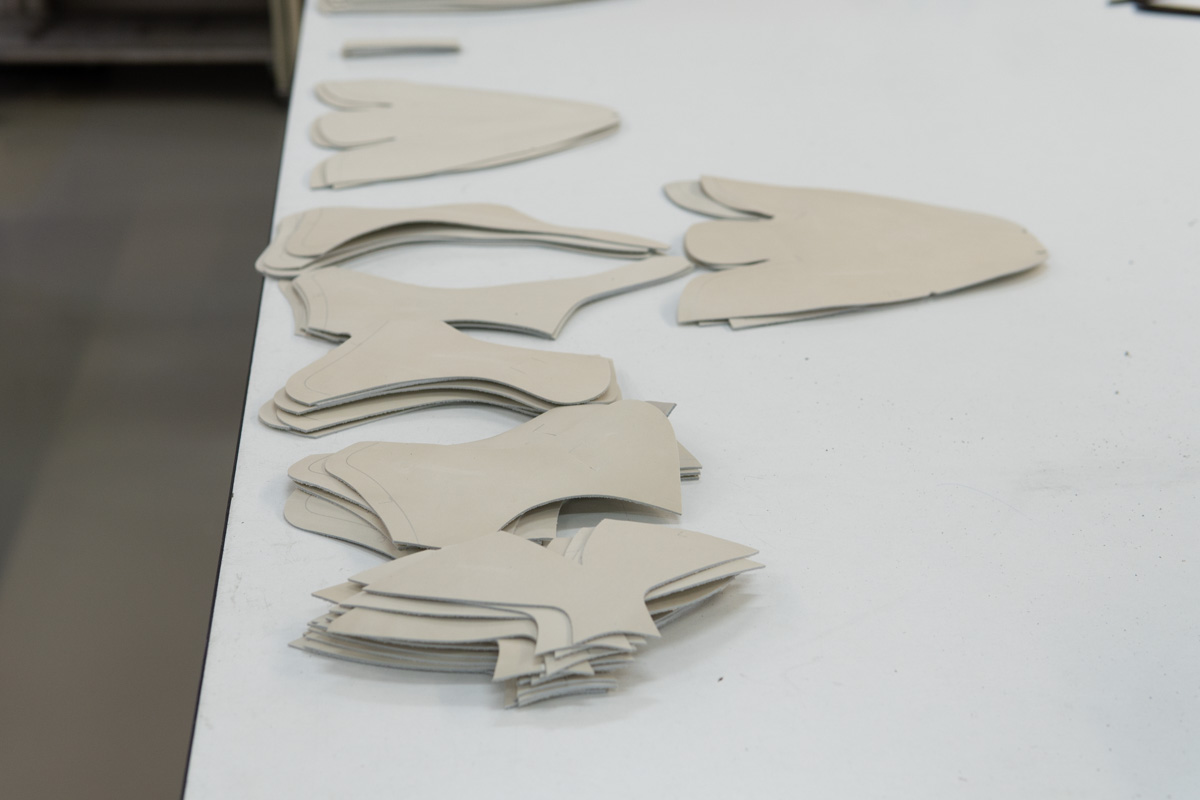

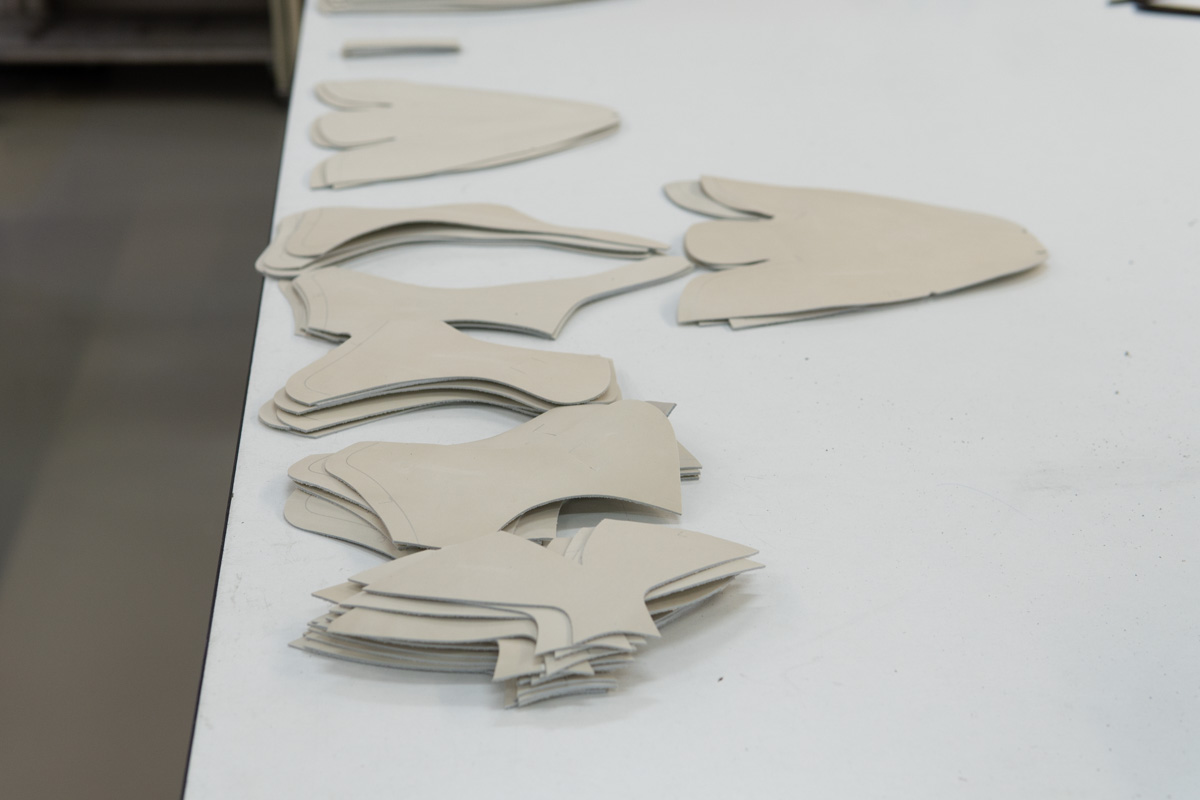

Animals live an actual life and just as humans, develop skin conditions, get scratches and markings and of course have veins.

With Hermes owning the best tanning facilities in France and reserving 80% of the best leather, what remains is very different.

You cannot (well, you shouldn’t) make quality shoes from the parts with veins as often clients will consider this a defect.

A lot of the leather ends up wasted and thrown away after removing and cutting the good pieces.

In the Carlos Santos Factory the pattern is projected by laser on the hide and then pressed to cut pieces perfectly.

These pieces undergo a process called skiving in certain areas that interconnect since two pieces are too thick to join together seamlessly otherwise.

With glue and reinforcement on more delicate areas, the stitching begins to close and create what we call the uppers.

A similar piece is also made from softer material to create the lining and then join them together.

Now it’s time to begin making the shoes.

Making The Shoes

The process in most Goodyear Welted Shoe Factories will be the same.

It follows a logical flow in usually an oval or round shape and begins with the shoes receiving form and lasting.

Lasting is a crucial part of shoemaking as it stretches the leather onto the form and prevents air and eliminates certain risks.

Doing it by hand is challenging, but thankfully machines can now press it in a matter of seconds.

As you see above humans still have to do work and need experience to operate the machines.

Welting & Filling

The next main part will be to attach the welt, which is the leather piece which interconnects the uppers and the outsole.

That little thing is what makes this construction robust and transforms the shoe into a resoleable marvel.

Once that is in place, you can proceed with adding the shank and the filler material.

It reinforces the parts of the shoe that receive a lot of tension.

The remaining is a filler of cork and hot glue (there are varieties) that spreads like a paste.

Of course, there are steps in between and minor adjustments such as trimming but not important to describe in detail.

Outsole & Finishing

At this stage, you can add the outsole and create the heel block.

There can be differences since you could do a hidden stitch channel which requires peeling off a layer of the outsole.

The regular ones just have a channel groove and stitching usually all the way to the heel start.

Heel blocks can be stacked or pre-built but for me the only real difference is when you need to repair something.

After that, you can remove the protecting covering and finish the shoes with polish or dye if you are doing patina work.

It sounds simple, but it is an elaborate process that needs experience and love.

A Place I Could Work

I love factory visits and it’s genuinely a place I could see myself working in some capacity.

The Carlos Santos Factory is newly built and very proficient and organized.

I would say much more compared to some others I checked in Spain for example.

I wish I could show you more pictures of the machinery and operation, but for privacy we could not.

Due to the nature of a workshop it’s also hard to do proper photography as the light conditions are not optimal.

Revisiting the Carlos Santos Factory in 2023 reminded me why I loved it the first time and why it was worth starting this business.

I hope you enjoyed this short article of me rambling about shoes and shoemaking.

Remember you can always get the best, most exclusive Carlos Santos Shoes only at The Noble Shoe.

Until next week my friends!

Thank you for reading,

Kostas Mandilaris,

Misiu Academy